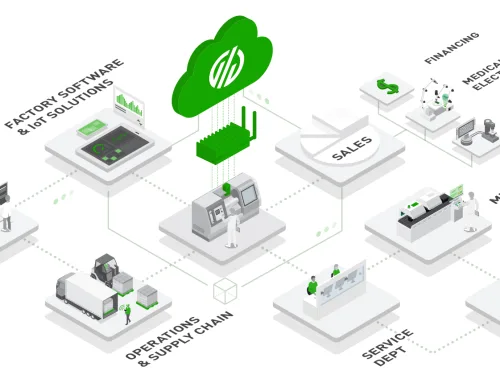

In the fast-evolving landscape of manufacturing, real-time monitoring has become a crucial component for optimizing operations. The advent of Internet of Things (IoT) technology has revolutionized how manufacturers monitor their processes, assets, and resources in real-time. This blog post delves into the various applications of IoT for real-time monitoring in manufacturing, highlighting its significance in maximizing efficiency and productivity.

Enhancing Equipment Performance with IoT

IoT enables manufacturers to monitor equipment performance in real-time, capturing data on parameters like temperature, pressure, and vibration. This data is then analyzed to detect anomalies, predict potential failures, and schedule preventive maintenance. By leveraging IoT applications, manufacturers can proactively address equipment issues, minimize downtime, and optimize production output.

Improving Inventory Management and Supply Chain Visibility

IoT facilitates real-time tracking of inventory levels, movement of goods, and supply chain activities. With IoT sensors and RFID technology, manufacturers gain visibility into the entire supply chain, from raw material procurement to finished product distribution. This enhanced visibility enables better inventory management, reduces stockouts, and improves overall supply chain efficiency.

Ensuring Quality Control and Compliance

IoT plays a vital role in quality control by providing real-time insights into product quality parameters. Sensors embedded in manufacturing processes collect data on product specifications, tolerances, and deviations. Manufacturers can monitor quality metrics in real-time, identify defects early, and take corrective actions to maintain high-quality standards. Additionally, IoT helps ensure regulatory compliance by tracking and documenting processes, ensuring adherence to industry standards.

Optimizing Energy and Resource Management

IoT applications enable manufacturers to monitor energy consumption, resource utilization, and environmental conditions in real-time. Smart sensors and meters collect data on energy usage, water consumption, and waste generation. By analyzing this data, manufacturers can identify opportunities for energy savings, optimize resource allocation, and implement sustainable practices. IoT-driven insights empower manufacturers to make data-driven decisions for efficient resource management.

In conclusion, IoT applications for real-time monitoring are revolutionizing the manufacturing industry. From enhancing equipment performance and inventory management to ensuring quality control and optimizing resource utilization, IoT offers a myriad of benefits for manufacturers.

Unlock the potential of IoT and propel your manufacturing operations towards greater efficiency and productivity today!

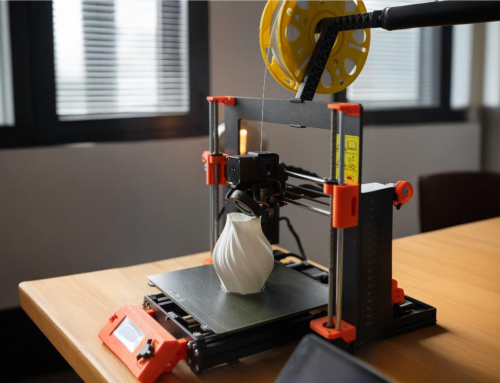

Join us in reimagining the future of logistics with Ionic3DP’s cutting-edge robotics solutions!

You can contact us now,

– Email : info@ionic3dp.com

– Phone : +91 8825958660

– Website : https://ionic3dp.com/