Major Features

Dual Extruder

Printing with Complex materials

Build volume

Tool Changer Mechanism

Hotbed

The Omega Pro comes with the ToolChanger mechanism which allows you to use four different tool heads for a single print job.

Omega Pro is a fully enclosed machine and comes with HEPA filters for enclosure ventilation. HEPA filters also help trap nano particles that are emitted during the printing process.

Omega is fitted with a built-in camera. Connect over wi-fi and check your printing process from anywhere.

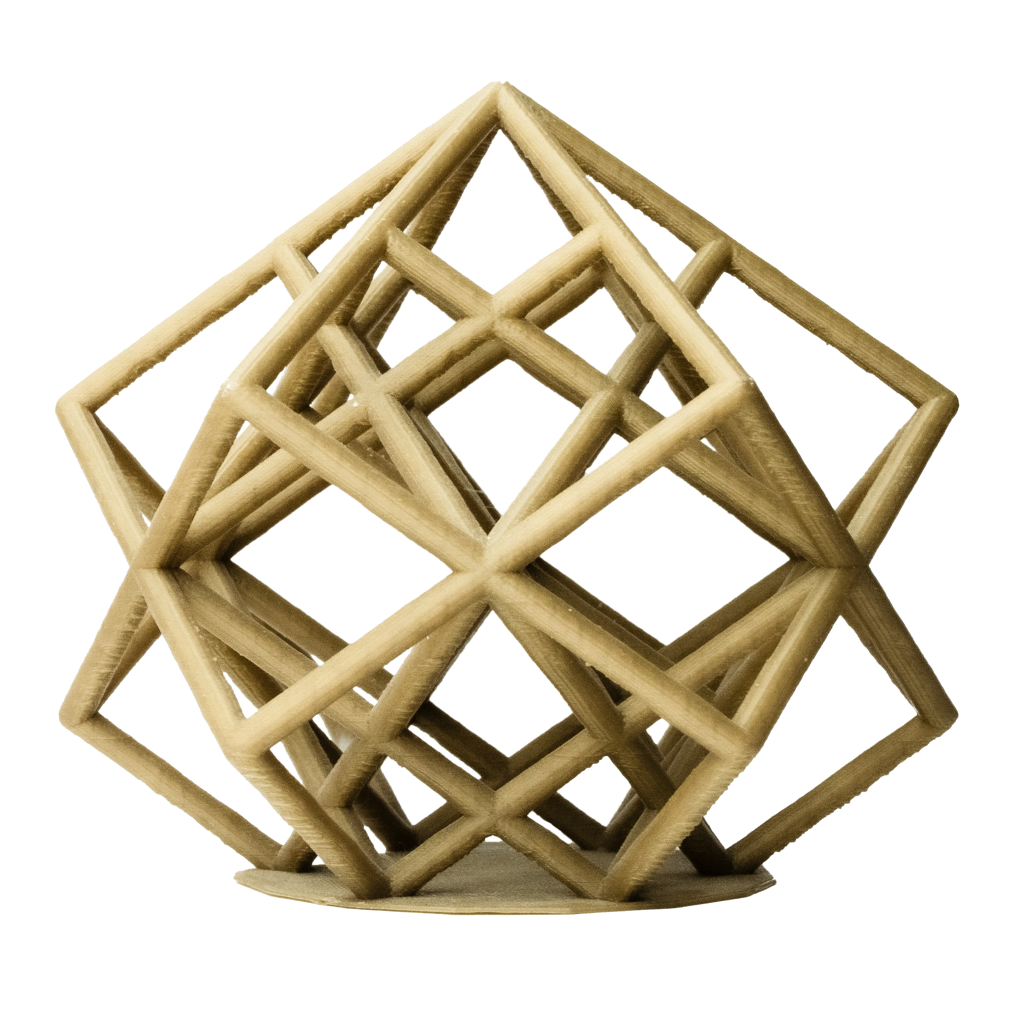

The Omega encompasses a large build up to a height, width and length of 550mm. Build complex structures with an Omega Pro 3D printer.

The printhead is fitted with a 3D touch sensor for the auto bed levelling system. The firmware ensures to adjust and maintain a uniform distance from the bed through the course of printing.

Omega – Pro Technical Specification

| Column 1 | Column 2 |

|---|---|

|

|

| Column 1 | Column 2 |

|---|---|

|

|

| Column 1 | Column 2 |

|---|---|

|

|

| Column 1 | Column 2 |

|---|---|

|

|

Omega – Pro Technical Specification

- Build area: 550 * 550 * 550mm

- Minimum print layer thickness: 50 microns

Maximum print layer thickness: 300 microns

- Material Diameter: 1.75mm

Printing accuracy: 100 to 150 microns

- Feeder type : Filament Fed

- Hot Bed:Auto bed levelling with 3D touch sensor

- Operation screen: Touch screen

- Maximum working speed: 250 mm/sec

- Maximum print speed: 300 mm/sec

- Maximum extrusion temperature: 400°

- Maximum hot bed temperature: 120°

- Maximum feeding speed: 100 mm/s

Auto-restart after power shutdown: Yes

Open source software: Cura

Supported OS: Windows, MacOS and Linux

Supported Files: STL, OBJ, GCode

Offline Printing: Supported

- Plug-in integration: Wifi, SD card & USB

- Training: We provide training online or in person (on request).

- Warranty period: 1 year warranty for the printer

- Support: Technical support by our experienced and dedicated Engineers, detailed manuals, online resources and much more will be provided.