Imagine walking into a factory where robots and humans work seamlessly side by side, a place where machines predict failures before they happen, and production lines never stop. This is not a scene from a sci-fi movie but a glimpse into the future of manufacturing. Companies like Tesla and Siemens are already paving the way, integrating advanced AI and robotics into their production processes. For founders and CxOs of medium and large-scale companies, understanding and adopting these technologies could be the key to staying ahead in a competitive landscape.

The Evolution of Manufacturing

Manufacturing has always been at the forefront of technological innovation. From the invention of the assembly line by Henry Ford to the introduction of computer numerical control (CNC) machines, each leap has revolutionized how products are made. Today, the integration of artificial intelligence (AI) and robotics is driving the next significant transformation.

AI and robotics are not just about replacing human labor; they’re about enhancing efficiency, precision, and adaptability. According to a report by McKinsey, AI has the potential to create $3.5 trillion to $5.8 trillion in value annually across 19 industries, with manufacturing being one of the key sectors poised for massive benefits .

Beyond the Buzzwords: Practical Applications

While many articles touch on the broad benefits of AI and robotics, let’s delve into some of the less-discussed yet impactful applications:

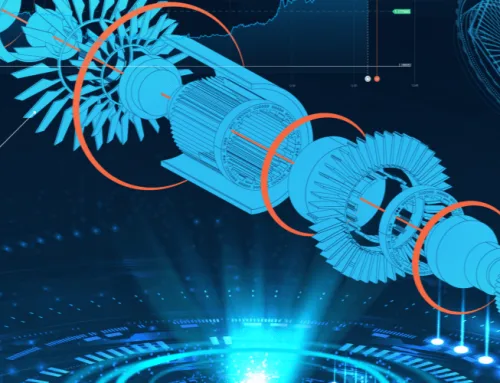

- Predictive Maintenance: Traditional maintenance schedules can be inefficient and costly. AI-driven predictive maintenance uses data from sensors on equipment to predict when a machine is likely to fail. This approach can reduce maintenance costs by 10-40% and cut downtime by 50% .

- Quality Control: AI-powered vision systems are transforming quality control. These systems can detect defects that are invisible to the human eye, ensuring a higher standard of quality. For instance, Landing.ai has developed a visual inspection platform that can identify tiny defects in products with a higher accuracy rate than human inspectors .

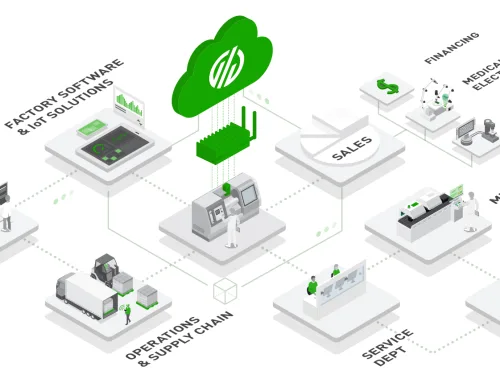

- Supply Chain Optimization: AI algorithms can analyze vast amounts of data to optimize supply chains in real-time. This means companies can respond to changes in demand, supply disruptions, and logistical challenges much faster than ever before. A case in point is how Procter & Gamble uses AI to manage its supply chain, resulting in improved service levels and reduced costs .

The Human Element

One of the biggest fears around AI and robotics is job displacement. However, the future of manufacturing is not about robots replacing humans but augmenting their capabilities. The World Economic Forum predicts that while 75 million jobs may be displaced by automation, 133 million new roles may emerge as companies adopt new technologies.

Challenges and Considerations

Adopting AI and robotics is not without its challenges. For CxOs, the following considerations are crucial:

- Data Security: With increased reliance on data, ensuring its security becomes paramount. Companies must invest in robust cybersecurity measures to protect their intellectual property and customer data.

- Skilled Workforce: There is a growing need for a workforce skilled in AI and robotics. Companies should invest in training programs to upskill their employees, ensuring they can work alongside advanced technologies.

- Initial Investment: The initial cost of integrating AI and robotics can be high. However, the long-term benefits often outweigh these costs, with improved efficiency and reduced operational costs leading to a significant return on investment.

Looking Ahead

The integration of AI and robotics in manufacturing is not a question of if, but when. Companies that embrace these technologies early will have a competitive edge, driving innovation and efficiency in their operations. For founders and CxOs, the challenge lies in navigating this transformation while balancing the human and technological elements. The future of manufacturing is here, and it is intelligent, automated, and incredibly exciting.

Ready to transform your manufacturing operations with AI and robotics? Contact us today to discover how we can help you integrate these cutting-edge technologies and gain a competitive edge. Let’s shape the future of manufacturing together!