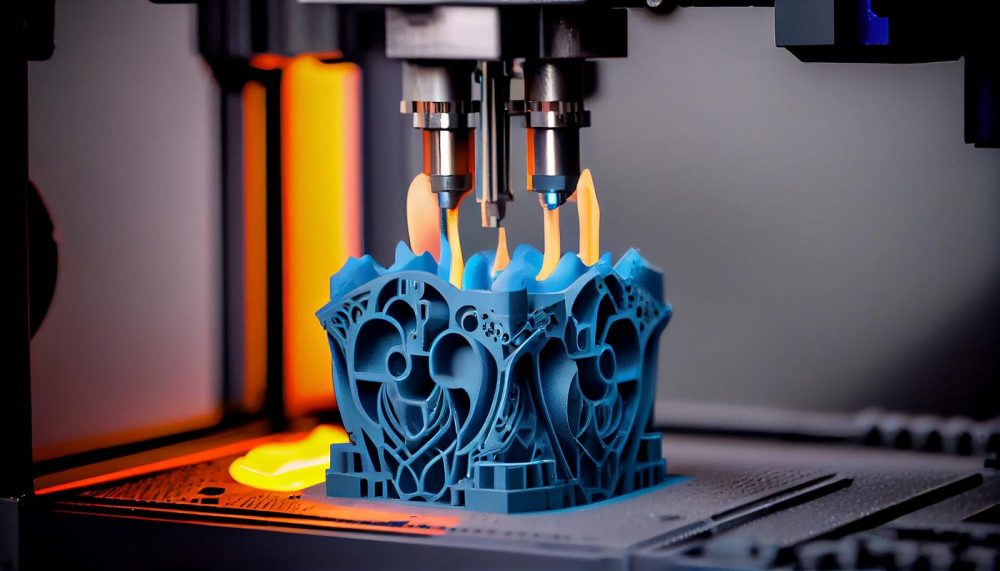

Picture a world where manufacturing is as simple as pressing “print.” A world where complex parts and prototypes materialize before your eyes, customized to perfection. This isn’t a futuristic dream—it’s the reality of 3D printing technology today. Founders and CxOs of medium and large-scale companies are increasingly turning to 3D printing to innovate, cut costs, and gain a competitive edge. Let’s explore the latest trends in 3D printing that are pushing the boundaries of what’s possible.

The Evolution of 3D Printing

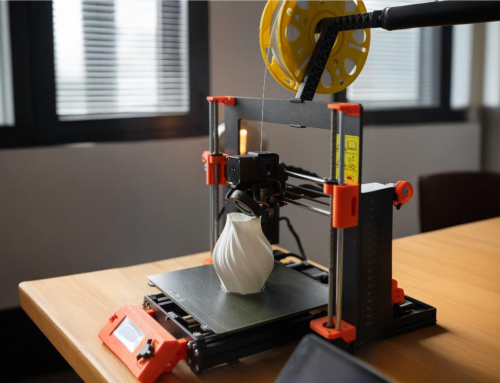

3D printing, also known as additive manufacturing, has come a long way since its inception in the 1980s. Initially used for prototyping, it has evolved into a versatile technology capable of producing everything from simple tools to complex aerospace components. According to Grand View Research, the global 3D printing market size was valued at $13.78 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 21.0% from 2021 to 2028 .

Beyond Prototyping: Innovative Applications

While many articles discuss 3D printing’s role in prototyping, let’s delve into some less-covered, yet highly impactful applications:

- Bioprinting and Healthcare: One of the most exciting advancements in 3D printing is bioprinting. This involves creating tissue and organ structures layer by layer, potentially transforming healthcare. Companies like Organovo are already working on printing human tissues for drug testing and research, paving the way for future organ transplants.

- Construction and Architecture: 3D printing is revolutionizing the construction industry. Large-scale 3D printers can now print entire buildings. The first 3D-printed office building, located in Dubai, was completed in just 17 days and cost 50% less than conventional construction methods. This technology promises to reduce waste, lower costs, and speed up construction times significantly.

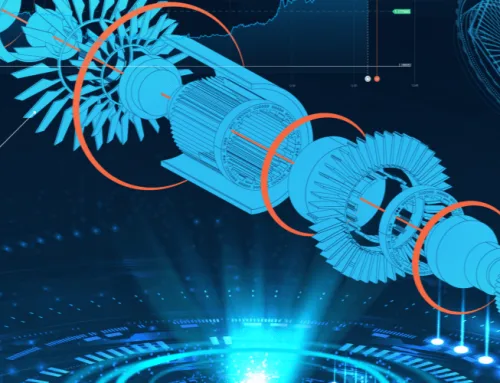

- Aerospace and Defense: The aerospace industry is leveraging 3D printing for lightweight and complex parts that are difficult to produce with traditional methods. GE Aviation, for example, has successfully 3D printed fuel nozzles for jet engines, making them 25% lighter and five times more durable than their predecessors.

The Sustainability Factor

One of the less-discussed benefits of 3D printing is its potential for sustainability. Traditional manufacturing often involves significant waste, but 3D printing uses only the material needed to create an object, reducing waste by up to 90% . Moreover, 3D printing allows for the use of recycled materials, further enhancing its environmental benefits. A study by Michigan Technological University found that 3D printing products at home using recycled plastic reduces energy use and carbon emissions by about 90% compared to traditional manufacturing.

Looking Ahead

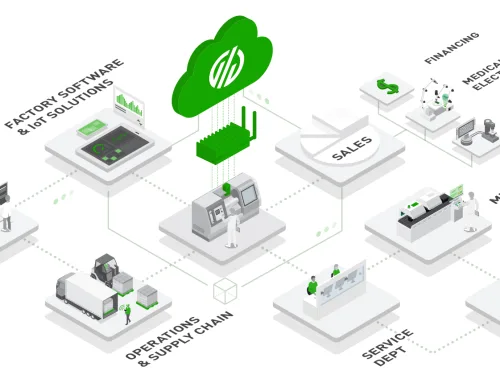

The future of 3D printing is incredibly promising. As the technology continues to evolve, it will open up new possibilities for innovation and efficiency. For founders and CxOs, staying abreast of these trends is essential for maintaining a competitive edge. By exploring and investing in 3D printing technology, companies can not only streamline their operations but also pioneer new products and solutions that were once unimaginable.

Is your company ready to harness the power of 3D printing? Explore the latest trends and innovative applications that can drive your business forward.

Contact us today to learn how we can help you integrate this game-changing technology into your operations. Embrace the future of manufacturing now!