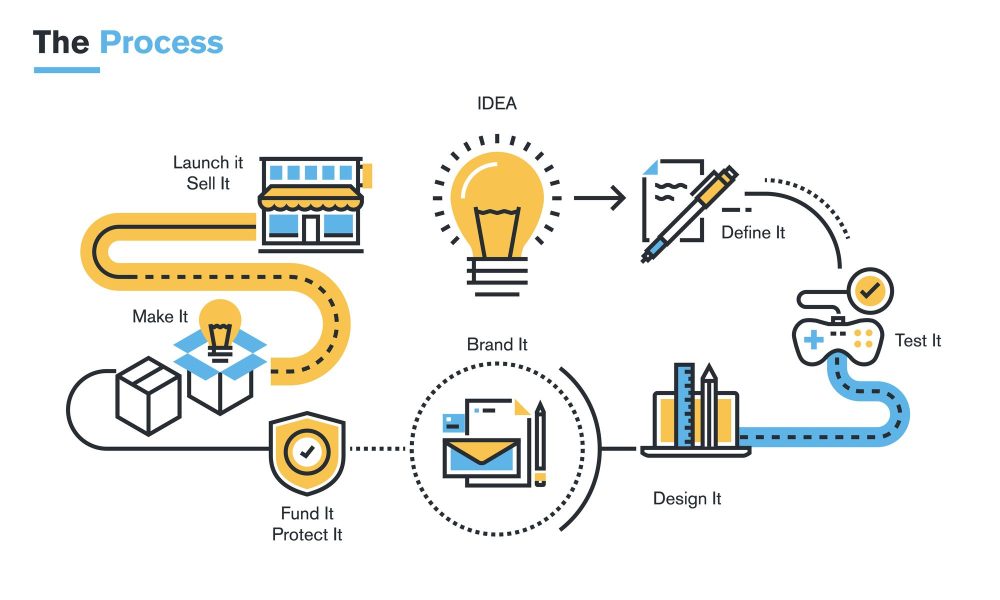

A Journey from Idea to Reality

Imagine you’ve just designed an innovative product prototype that has the potential to revolutionize your industry. The prototype works flawlessly in the lab, and initial feedback from stakeholders is overwhelmingly positive. But as you prepare to scale up for mass production, new challenges emerge. How do you maintain the quality, manage costs, and ensure timely delivery? This transition from prototype to production is a critical phase that can make or break your product’s success.

Understanding the Transition

The transition from prototype to production involves moving from a small-scale, often hand-crafted version of your product to a full-scale manufacturing process. This phase requires meticulous planning and coordination to ensure that the final product meets all design specifications and quality standards.

Key Challenges in Scaling Up

1. Quality Control

Maintaining the same level of quality in mass production as in the prototype can be challenging. Small imperfections that were acceptable in a prototype can become significant issues when scaled up.

Solution: Implement robust quality control processes and use advanced technologies like AI-driven inspection systems to ensure consistency.

2. Cost Management

Production costs can skyrocket if not carefully managed. Factors like material costs, labor, and production time need to be optimized.

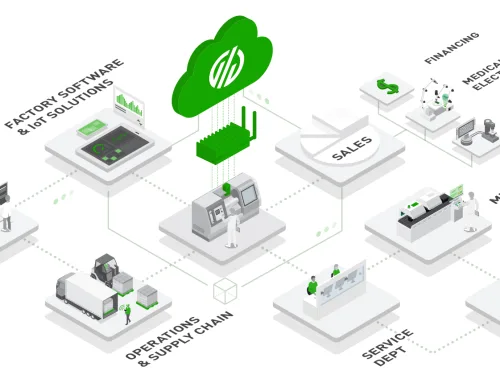

Solution: Utilize cost-effective materials and streamline production processes through automation and efficient supply chain management.

3. Production Timelines

Meeting production deadlines is crucial for timely product launches. Delays can lead to missed market opportunities and financial losses.

Solution: Develop a detailed project timeline with buffer periods to handle unexpected delays. Use project management tools to track progress and ensure timely completion.

Innovative Solutions for Smooth Scaling

1. Digital Twins

Creating digital twins of your production process allows for simulation and optimization before actual production begins. This helps identify potential issues and streamline processes.

2. Lean Manufacturing

Implementing lean manufacturing principles can significantly reduce waste and improve efficiency. Focus on continuous improvement and value addition at every stage.

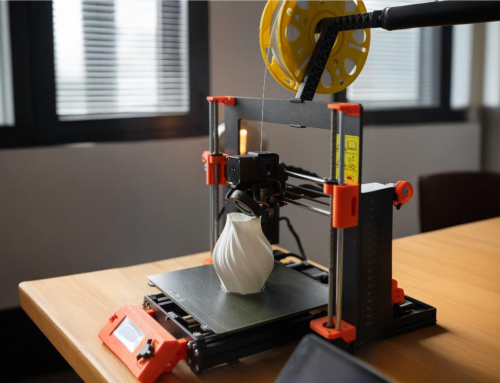

3. Advanced Prototyping Technologies

Using advanced prototyping technologies like 3D printing can speed up the development process and allow for rapid iterations and adjustments.

Turning Challenges into Opportunities

Scaling from prototype to production is a complex but rewarding journey. By understanding the challenges and implementing innovative solutions, you can ensure a smooth transition and a successful product launch. At Ionic3DP, we specialize in helping businesses navigate this critical phase with our expertise in customized products and advanced manufacturing technologies.

Ready to streamline your transition from prototype to production? Contact us today to ensure your product’s success in the market.