A Tale of Two Workers

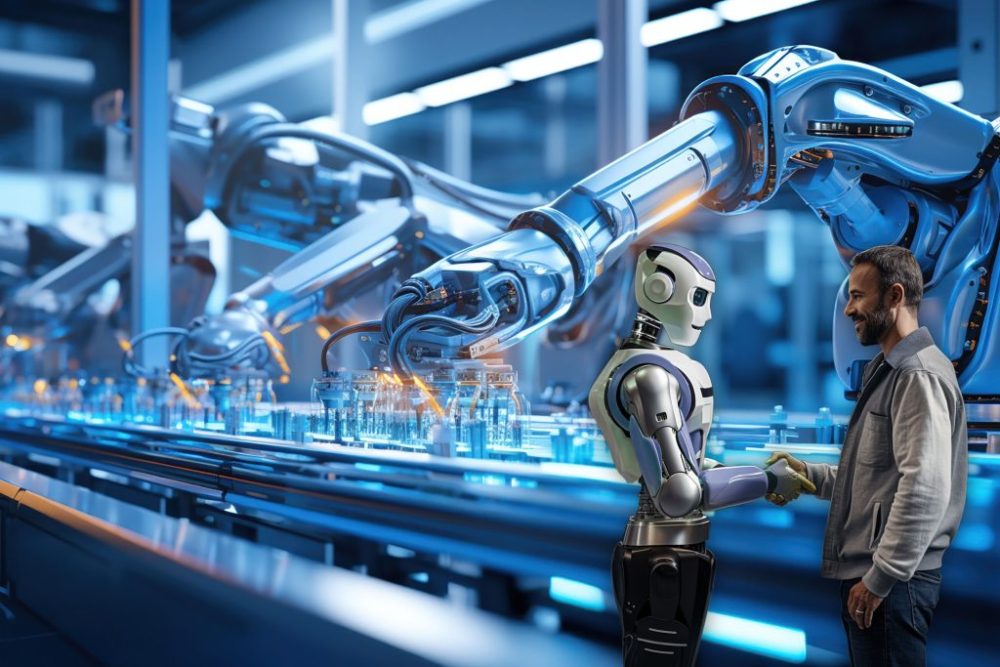

Imagine a bustling factory floor where human workers and robots move in perfect harmony. John, a skilled technician, stands side by side with his robotic counterpart, R1. While John focuses on the intricate details of assembly, R1 handles the repetitive tasks, never tiring, never slowing down. This isn’t science fiction; it’s the future of manufacturing, where human-robot collaboration is transforming how we produce goods.

This scenario isn’t just a glimpse into what’s possible; it’s already happening in cutting-edge manufacturing environments. But as we delve deeper into this new era, how can companies effectively enhance human-robot collaboration to maximize efficiency, safety, and innovation?

The Rise of Human-Robot Collaboration

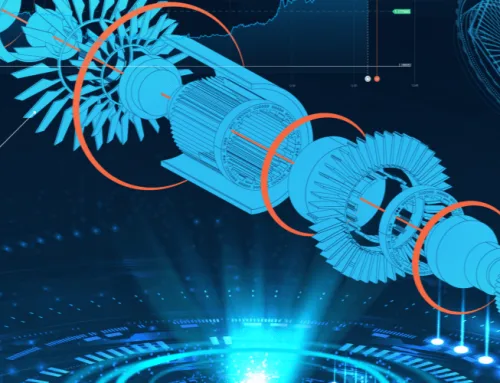

The Evolution of Manufacturing: The integration of robots in manufacturing isn’t new, but the role they play has evolved. Early robots were isolated, performing repetitive tasks in cages to ensure human safety. Today, collaborative robots (cobots) work directly alongside humans, thanks to advancements in sensors, AI, and machine learning. This evolution has paved the way for enhanced human-robot collaboration, where both entities complement each other’s strengths.

The Benefits of Collaboration: Human-robot collaboration brings numerous benefits to the manufacturing floor:

- Increased Efficiency: Robots handle repetitive and physically demanding tasks, allowing humans to focus on more complex and creative aspects of production.

- Enhanced Safety: Modern cobots are equipped with advanced sensors that detect human presence, ensuring safe interaction and reducing workplace accidents.

- Flexibility and Adaptability: Human workers can easily reprogram and reconfigure cobots for different tasks, providing unparalleled flexibility in a fast-changing manufacturing environment.

- Improved Product Quality: The precision of robots combined with human oversight results in higher quality products and fewer errors.

Strategies for Enhancing Human-Robot Collaboration

- Invest in Training and Skill Development: One of the key challenges in human-robot collaboration is ensuring that human workers have the skills needed to work effectively with robots. This includes not only technical training but also fostering a mindset open to innovation and change.

- Designing Workspaces for Collaboration: Manufacturing spaces must be redesigned to accommodate human-robot teams. This means creating environments where robots and humans can work side by side without barriers, optimizing the flow of work, and ensuring safety.

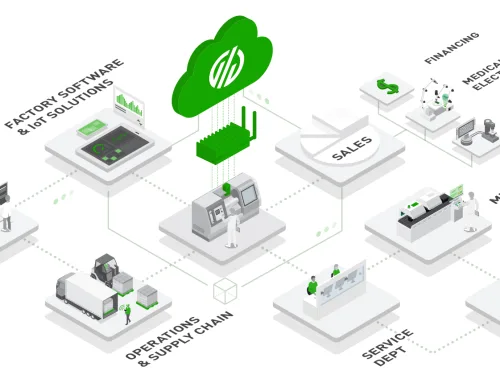

- Leveraging AI and Data Analytics: Integrating AI and data analytics into human-robot collaboration can lead to smarter, more responsive manufacturing systems. AI can help predict maintenance needs, optimize workflows, and even suggest improvements in real-time, enhancing the synergy between humans and robots.

- Focus on Safety and Ergonomics: While robots can handle heavy lifting and repetitive tasks, human workers should be protected from ergonomic risks. Collaborative robots should be programmed with safety protocols that prioritize human well-being, and workplaces should be designed to minimize strain and fatigue.

- Encouraging Continuous Improvement: Human-robot collaboration is not a set-it-and-forget-it solution. It requires continuous monitoring and improvement. Encourage teams to regularly assess the effectiveness of collaboration, make adjustments as needed, and explore new ways to enhance efficiency and innovation.

Real-World Applications

Case Study: Automotive Industry: In the automotive sector, human-robot collaboration has revolutionized assembly lines. Robots perform tasks like welding and painting, while humans handle quality control and intricate assembly. This collaboration has led to faster production times, higher quality vehicles, and safer working conditions.

The Future of Human-Robot Collaboration

As manufacturing continues to evolve, the collaboration between humans and robots will become even more integral to success. Companies that embrace this synergy will not only enhance efficiency and safety but also drive innovation and remain competitive in a rapidly changing market.