Imagine a patient with a unique medical condition that requires a device tailored specifically to their anatomy. Traditional manufacturing methods struggle to meet the precision and customization demands of such a case. Enter adaptive re-engineering processes—a cutting-edge approach that’s revolutionizing how medical devices are developed. For businesses looking to stay ahead, this approach enables personalized medical solutions at an unprecedented level of accuracy, speed, and cost-efficiency.

In this blog, we explore how adaptive re-engineering processes are transforming the way small and large-scale businesses customize medical devices, and how Ionic3DP can help you innovate.

The Role of Adaptive Re-engineering in Medical Device Customization

- Addressing Unique Patient Needs Adaptive re-engineering processes focus on creating custom solutions tailored to individual patients. With healthcare moving towards personalized care, these methods allow medical devices to be modified based on specific anatomical and functional requirements, ensuring precision and patient comfort.

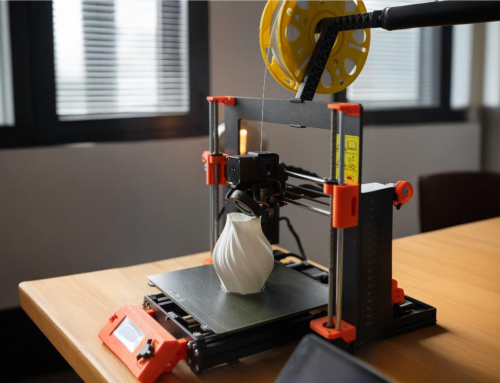

- Speeding Up Production Cycles Medical emergencies and the fast-paced nature of healthcare demand quick, reliable solutions. Adaptive re-engineering optimizes the design-to-production timeline by using advanced software tools and 3D printing. This allows for rapid prototyping, reducing the overall time to market for customized devices.

- Enhancing Device Accuracy and Quality In the medical field, there’s no room for error. Adaptive re-engineering processes integrate AI-driven tools that enhance the accuracy of medical devices by ensuring flawless designs. By iterating and fine-tuning designs based on real-time feedback, manufacturers can ensure that every device meets the highest standards of quality and safety.

- Reducing Costs for Custom Medical Devices Traditionally, customized medical devices were expensive and time-consuming to produce. However, with adaptive re-engineering, small and large-scale businesses can cut down on costs through efficient material usage, automation, and optimized processes. This opens up opportunities for cost-effective solutions without compromising quality.

- Supporting Innovation in Medical Technology The adaptability of this approach paves the way for continuous innovation in medical technology. With flexible and scalable re-engineering methods, businesses can stay competitive, constantly improving their products based on new insights, research, and technological advances.

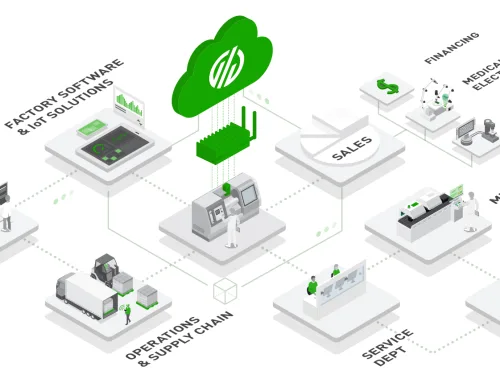

At Ionic3DP, we specialize in adaptive re-engineering processes to create custom medical devices that meet your unique requirements. Whether you’re a small startup or a large enterprise, our team offers the tools and expertise to transform your vision into reality. From design to prototyping and final production, we ensure that every step is optimized for precision, speed, and cost-effectiveness.

Ready to innovate? Contact us today to explore adaptive re-engineering solutions for your custom medical devices.